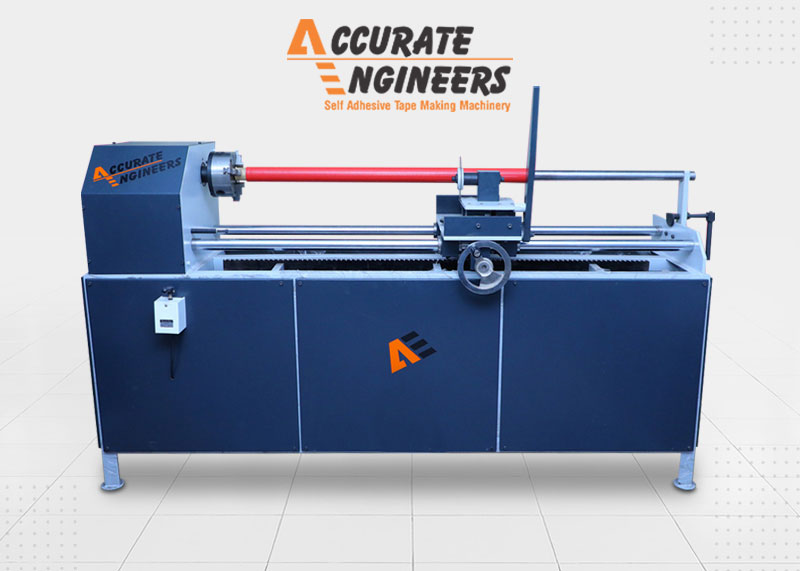

Tape Making Machine – Made With the Latest Technology

In India, we are a leading Tape Making Machine manufacturers in India. Our machines are built in line with the standards and are available in a variety of types, sizes, and production speeds to meet the technical requirements of our clients. These are used in a variety of industries and are also reasonably priced. By pushing the adhesive through a very small slot, the adhesive is applied extremely thinly on the backing with the solvent. The coated backing is then sent through a drying tunnel, where the solvent evaporates. Following the drying process, the adhesive tape coating solidifies and is securely attached to the backing, followed by the winding and slicing of the tape rolls. We offer the machines in a variety of customizable solutions to satisfy the diverse needs of clients.

Buy Top-Notch Tape Making Machine

We are an eminent Tape making machine suppliers in India. The roll is put into the coating machine and one side is coated with adhesive.

The coated roll is put into the slitting machine, and the slit tapes are automatically coiled in the paper core of the desired width. We are offering tape making machine that consists of adhesive coating, drying and slitting, and rewinding into small tapes. The offered machine is becoming the best-selling entity in the segment as it features innovative controls for single-coated and double-coated taping products. Designed and developed following industry requirements, our quality specialists carefully test the provided machine to verify compliance with international manufacturing standards. Furthermore, this high-performance machine is available at a low cost in a variety of models and output capacities.

- Cost-Effective.

- Low Maintenance.

- Web guide system.

- Lamination station.

- Anti-corrosive body.

- Enhanced service life.

- User-friendly operation.

- Single/Double station Unwind.

- Manual / Pneumatic loading of parent roll.

- Mechanical/pneumatic brake at unwinding.

- Single station / Double station turret rewind.

- Friction clutch / auto-tension control for rewind.

- Multi-step temperature control for different zones.

- Rewinding shaft

- Rewinding shaft – 4nos.

- Power consumption- 6 HP

- Unwind Roll Weight – 500Kgs.

- Maximum Unwinding – 800mm

- Maximum Web Width – 1320mm

- Minimum Slitting Width – 25mm

- Maximum Rewinding – 1000 MTR

- Machine Speed – 150Meter/Minute

- Knurling roll- m .s with Teflon coating

- Anti-crazing device – 1 nos with gearbox

- Turret system – attached with one gearbox

- Turret system – attached with one gearbox

- Digital Electric Auto Stop Counter Meter. (Length Counting)

Packing Tape Making Machine

We are an eminent packing tape-making machine supplier in India.

Electrical Tape Making Machine

We are one of the most well-known Electrical tape-making machine suppliers in India

Paper Tape Making Machine

We are an eminent Paper tape-making machine manufacturers in India.

Packing Tape Manufacturing Machine

Accurate Engineers is recognized as one of India’s top Packing tape manufacturing machines manufacturers, suppliers, and exporters.