Masking Tape Making Machine – Easy to Maintain

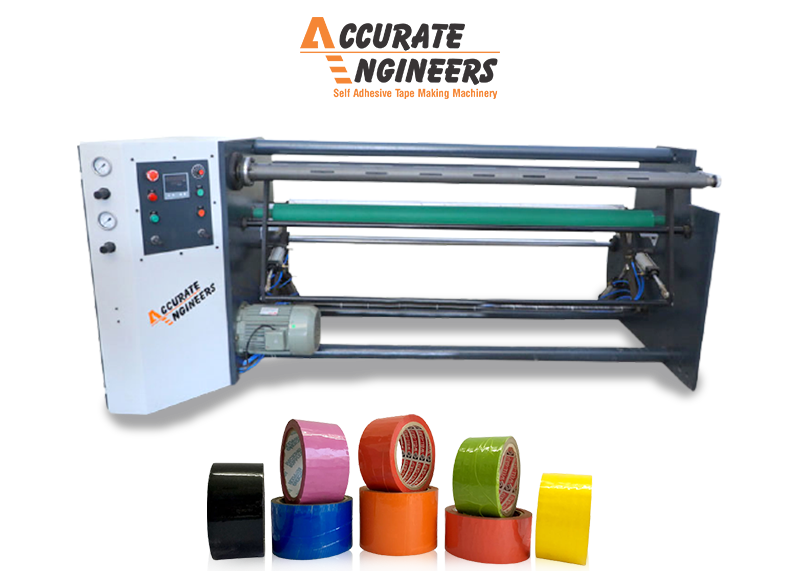

We are among the leading high-quality Masking Tape Making Machine manufacturers in India. The offered machine is outfitted with automated control panels that manage and regulate different activities such as winder drive, trim collection blower operation, and speed indicator. Also, We deliver these machines within the specified period thanks to our well-connected distribution network. The slitter rewinder machine is specialized equipment designed for slitting packaging film materials. The slitter rewinder plant is motor-operated and has a high rewind and unwind control panel. It guarantees precise roll slitting with consistent, faultless results and steady line speed.

This machine requires less manual assistance, and the independent roller integrated with the rewinder control system continues to provide faultless rewinding.

Top Brands of Masking Tape Making Machine

In Gujarat, we are a major Masking Tape Making Machine suppliers in India. Our offered machine is all-in-one (printing/coating/slitting) equipment that specializes in producing Masking Tape in a variety of sizes while conserving money. It consists of Adhesive, Coating, and Slitting. To begin, the adhesive is mixed with the solvent required to transfer it to the backing of the tape. Depending on the type of tape, a mix of adhesive and solvent is created. The backing roll should be coated, and once completed, we must wait for it to harden. The tape rolls are then made, which can be sliced into smaller pieces. We provide Masking tape-making machines in a variety of models and product lines.

- Energy efficient

- Smooth operation

- Optimum performance

- Clean and easy removal

- Auto silicon water spray cooling system

- Round blade cutting and pneumatic blade feeding

- Small, easy to maintain, cost-effective and efficient

- The working width ranges from 800mm to 1600mm

- Cutting width gauge to position width cutting quickly and reliably

- Linear construction with a basic structure that is simple to install and maintain.

- Production speeds: up to 150mpm are possible.

- 5 hp power consumption

Masking Tape Manufacturing Machine

We are counted among the successful masking tape manufacturer machine suppliers in India.