From sealing boxes to sticking up reminders, tape is an essential part of our everyday lives. They are used for various purposes in different sectors such as packaging to repairing. But have you ever wondered how these tapes are made? Here comes a tape making machine an essential tool for making tapes. In this blog post, you will learn everything about these machines, their types, and their applications.

What is a Tape Making Machine?

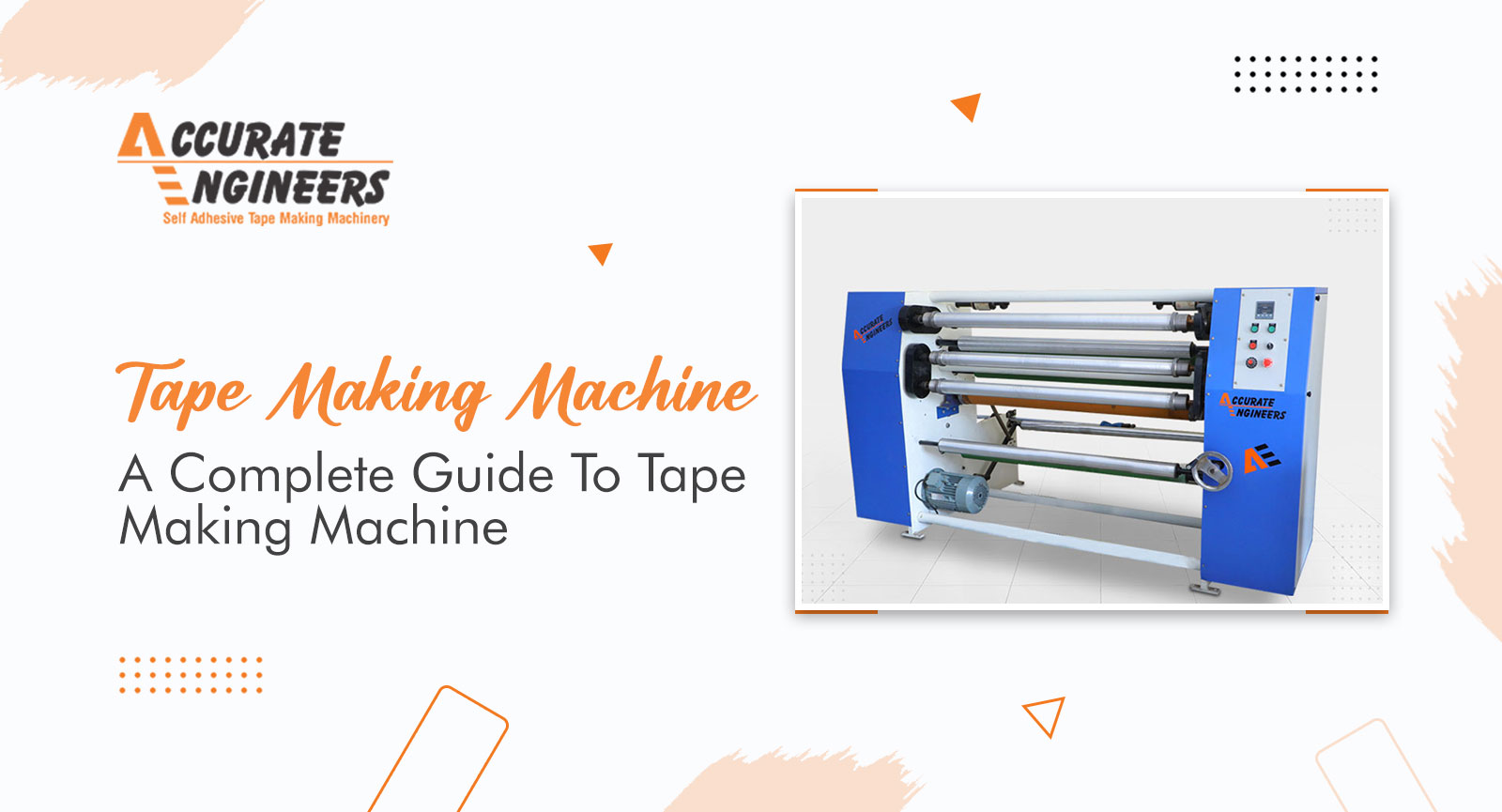

They are mechanical devices designed to manufacture adhesive tapes efficiently. These machines come in various types, ranging from simple manual devices to sophisticated automated systems. Regardless of their complexity, tape-making machines share common components:

Material Feeding Mechanism: Adhesive tape making machines utilize rolls of raw material, typically made of polypropylene, PVC, or other suitable materials. These materials are fed into the machine through a feeding mechanism, ensuring a continuous supply for production.

Coating Unit: Once the raw material is fed into the machine, it passes through a coating unit where adhesive is applied uniformly on one side of the material. The coating process ensures proper adhesion and durability of the tape.

Drying System: After the adhesive is applied, the tape passes through a drying system, which accelerates the drying process, ensuring quick curing of the adhesive.

Cutting and Winding Mechanism: Once the adhesive is dried, the tape is cut into desired lengths and wound onto reels or spools. This mechanism ensures precision in tape dimensions and facilitates easy handling and storage.

Types of Tape Making Machines:

Manual Tape Making Machines: These machines are operated manually, with operators feeding raw materials and overseeing the production process. While manual machines are cost-effective and suitable for small-scale operations, they require more labor and are less efficient compared to automated systems.

Semi-Automatic Tape Making Machines: Semi-automatic machines combine manual operation with automated processes. Operators feed raw materials into the machine, while the machine handles the coating, drying, and cutting processes automatically. Semi-automatic machines offer higher efficiency and productivity than manual machines while still being affordable for medium-sized businesses.

Fully Automatic Tape Making Machines: Fully automatic machines are equipped with advanced sensors, controllers, and robotic mechanisms that handle the entire production process from material feeding to finished tape winding. These machines offer unparalleled speed, precision, and efficiency, making them ideal for large-scale manufacturing operations.

Applications of Tape Making Machines:

Construction Sector: In the construction sector, specialized tapes manufactured by tape manufacturing machines are used for sealing joints, repairing surfaces, and securing insulation materials. These tapes offer weather resistance, strong adhesion, and durability, making them ideal for construction applications.

Packaging Industry: Cello tape making machines are extensively used in the packaging industry for sealing cartons, boxes, and packages. The durable and reliable sealing provided by adhesive tapes ensures product integrity during storage and transit.

Automotive Manufacturing: Tape manufacturing machines play a crucial role in the automotive industry for manufacturing adhesive tapes used in vehicle assembly. These tapes are utilized for bonding components, securing wires, and providing insulation, contributing to the structural integrity and longevity of automobiles.

Medical Sector: In the medical sector, tapes manufactured by BOPP tape making machines are used for wound dressing, surgical procedures, and medical device assembly. These tapes are designed to be hypoallergenic, breathable, and gentle on the skin, ensuring patient comfort and safety.

Conclusion:

Tape making machines represent a cornerstone of modern manufacturing processes, offering efficiency, reliability, and versatility across various industries. Whether it’s for packaging, construction, automotive, or medical applications, these machines play a vital role in ensuring product quality, safety, and efficiency. Understanding the different types of tape manufacturing machines and their applications is essential for businesses seeking to optimize their production processes and stay ahead in today’s competitive market landscape.

Accurate Engineers

Accurate Engineers was established in 1992 and has developed an effective electrical tape making machine by utilizing high-grade technical advances and custom-made configurations.