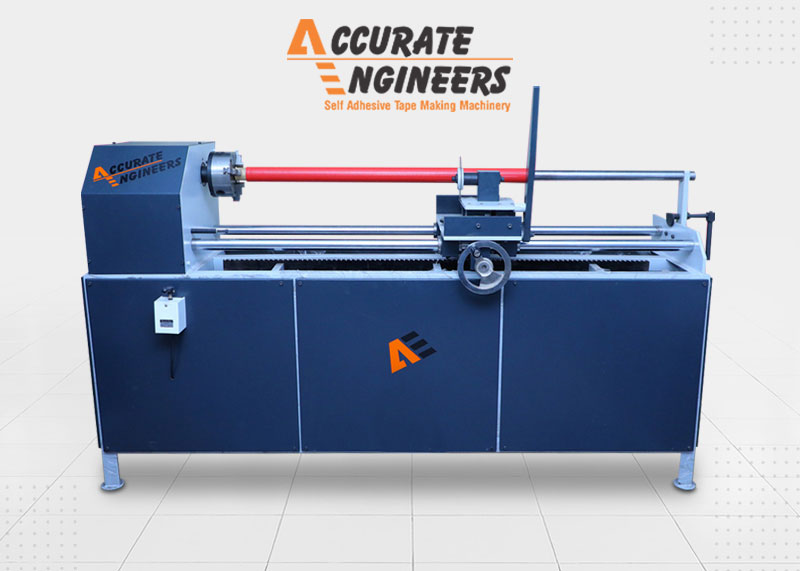

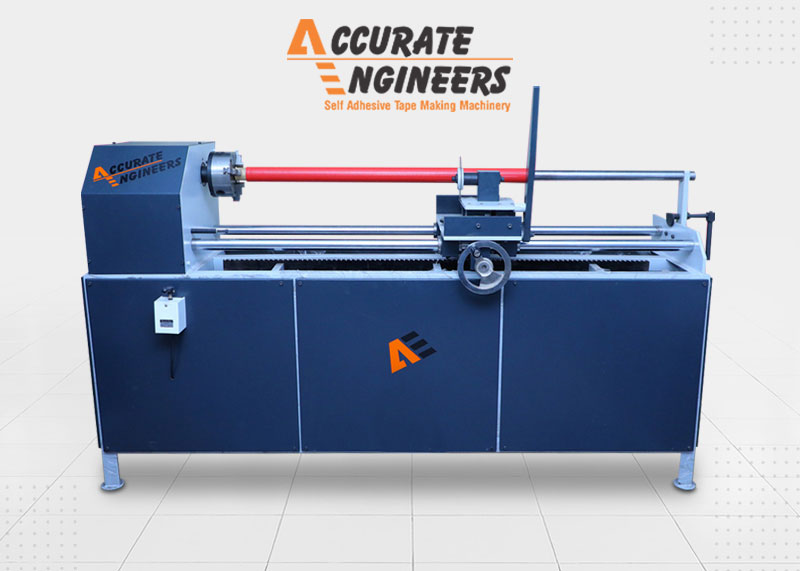

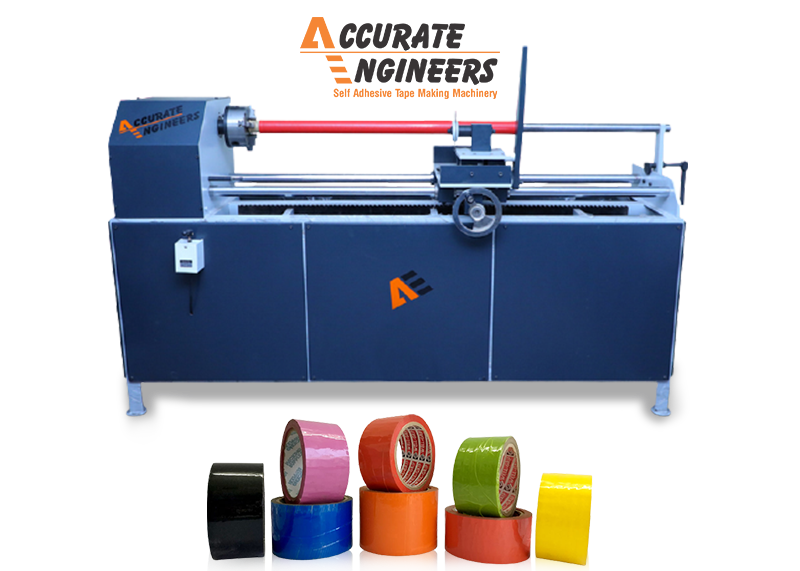

Insulation Tape Cutting Machine – Delivers High Results

Accurate Engineers has carved out a niche in the market by providing high-quality Insulation tape cutting equipment. We are one of India’s leading Insulation tape cutting machines manufacturers in India. Our equipment is intended for long-term heavy-duty operations, particularly cutting in diameters ranging from 12 to 1000 mm. Our offered machine has been extensively verified against various quality standards and is widely utilized in several sectors. To assure the characteristics and cutting-edge technology of the given equipment, we employ high-quality raw materials purchased from one of the industry’s most trustworthy and top sources at our manufacturing plant.

Its high strength shaft,wear resistance&compression resistance makes it suitable for long-term cutting completion.

Get a High-Grade Insulation Tape Cutting Machine

Also, its efficient PLC human-computer interface control systems simplify operations,minimize the likelihood of job errors, and significantly enhance production efficiency, and its high fortitude Tungsten steel blades, which are sharp,light&thin, may provide long-term high-efficiency cutting. We also manufacture machines for specific purposes based on customer requests that too at reasonable prices.We are among the prominent&leading Insulation tape cutting machines suppliers in India and our offered machine is well-known among clients. The slitter rewinder plant is motor-powered&features a high rewind&unwind control panel. This machine requires less manual assistance, and the rewinder control system’s independent roller continues to deliver flawless rewinding.

- Optimum strength & High-efficiency

- Precisely engineered

- Once selecting the cutting length and quantity, it can cut automatically.

- If the materials run out during the operation, it will automatically stop.

- High-speed:can cut100-120pcs/min

- Accurate cutting length

- Hot&Cold Cutting Knives:It can simply switch between hot&cold cutting.

- Material feeding will be in roll form only

- Separate unwind station to make jumbo rolls into a small roll for the slicing machine

- Less wastage