Abro Tape Making Machine – Quick to Use

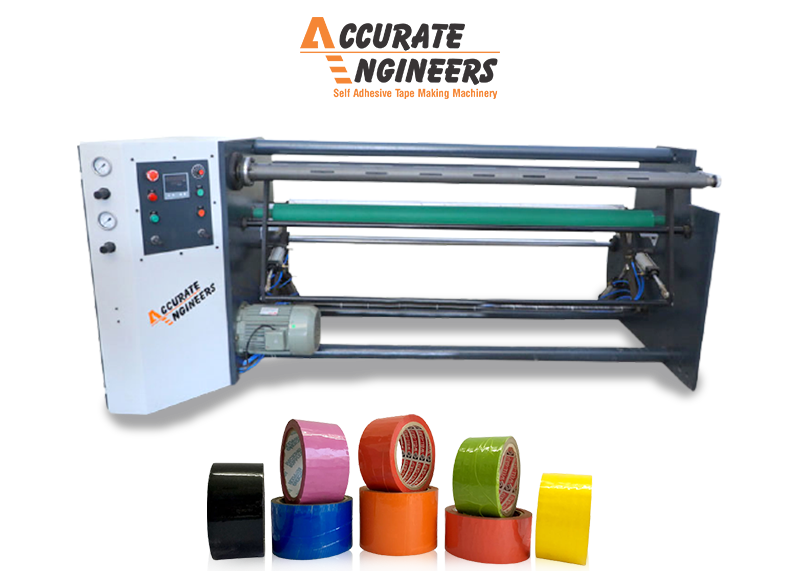

We are a top Abro tape-making machine manufacturers in India. We manufacture it using high-grade inputs and the latest technology in strict accordance with international quality standards. We deliver these machines in both standard and customized specifications according to the varied requirement of our esteemed clients. We have our Research and Development department, which is comprised of brilliant engineers with years of expertise. We are committed to providing top-quality items to customers. This Abro tape-making machine is less costly, saving you money and time since it removes the requirement for drying time, and the tape is easy to apply and adheres effectively to difficult-to-stick surfaces.

The machines available are outfitted with completely automatic control panels that manage and regulate a variety of activities such as winder drive, trim collection blower operation, and speed indicator.

Buy From the Leading Abro Tape Making Machine Suppliers

It is equipped with high rewind and unwinds control panel and it is motor-driven. This machine requires less manual assistance, and the independent roller, which is equipped with a rewinder control system, stays efficient for faultless rewinding. We are a leading Abro tape-making machine suppliers in India. Because of its compact size, the Abro tape-making machine is portable. It is less cumbersome and easier to move to other locations. An Abro tape-making machine looks appealing and is resistant to most environmental damages. They are quick to complete their jobs, which saves time and increases production. They are available in a wide range of models with varying sizes and performance levels at amazingly affordable prices.

- Maximum Web Width – 1600mm.

- Brake(rewindingside) – mechanical.

- Rubber roll pressure – pneumatic.

- Machine Speed – 80 Meter/Minute.

- Max. Unwind Roll Weight – 500 Kg.

- Drive – 5 hp ABB/Schneider.

- Rewind shaft – Air shaft 1 NOS.

- 5 HP.A.C. Motor and Drive panel.

- Control panel attached with machine.

- Digital Electric Auto Stop Counter Meter. (Length Counting)

- Optimum performance

- Energy efficient

- Smooth operation

- Quick to use

- Precise composition

- Highly effective

- Longer service life

- Fully MS structure.

- Manual tape cutting machine with 1350mm & 1600mm working width.

- Power consumption 2 hp.

- production capacity 7000no./day.