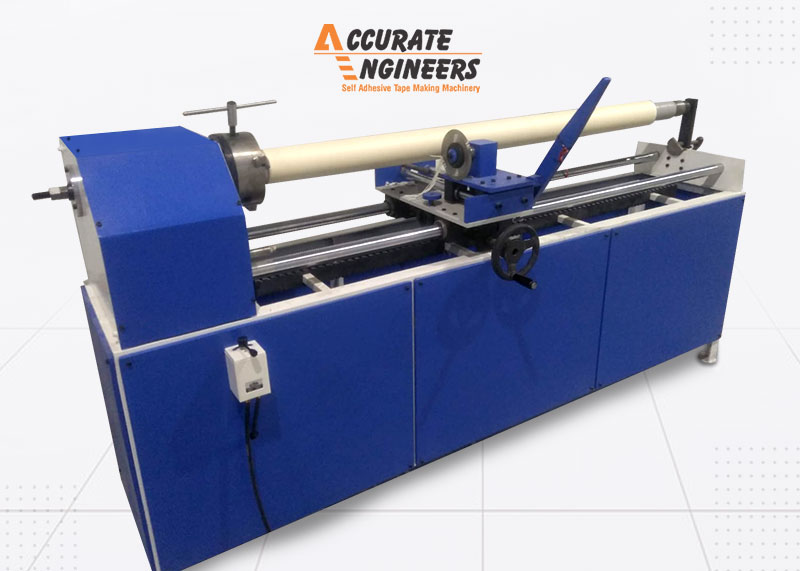

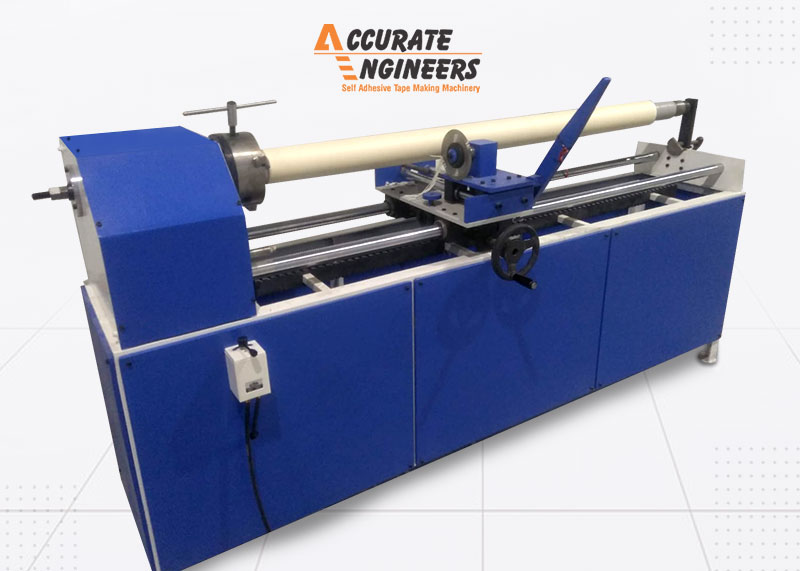

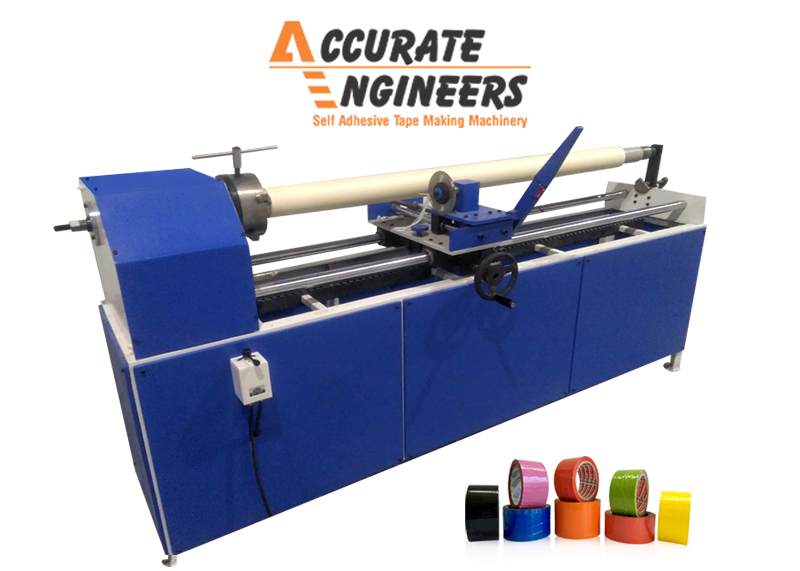

Easy Operated Abro Tape Cutting Machine

We are India’s most experienced Abro tape cutting machine manufacturers in India. To fulfill client demand, we manufacture, export, and provide high-quality Abro tape cutting machines based on our extensive industry experience and understanding. The product is manufactured utilizing high-quality raw materials and sophisticated technologies following the quality specifications. By sending a large roll of material through the slitter’s unwind, the material will be unwound, cut into various widths, and then rewound into various width cores. It comprise of an DC-AC drive motor, MS Sidewall, an Unwinder Rewinder System, an auto stop counter, a control panel, and other components.

Our machines are manufactured with a high level of quality in mind for long-lasting heavy-duty procedures, such as slitting/cutting in a variety of diameters starting at 12 mm.

Precisely Engineered Abro Tape Cutting Machine

This machine has made a major effect in the industry by offering outstanding quality Abro tape cutting by precisely controlling the tension of the unwinding Abro tape through pneumatic braking and rewinding. In India, we are a major Abro tape cutting machine suppliers in India. Our Cello tape cutting machine is a combination of rugged construction and exact dimensions obtained by paying great attention to requirements and utilizing high-quality SS material, while our innovative integration of the side frame provides vibration-free slitting and rewinding of the cello tape. This machine, which is available in a range of specifications and designs, is extensively used to cut Abro tape to highly exact tolerances. Furthermore, we provide this machine at a fair price to our customers.

- MaximumWeb Width – 1600m

- Sizing system – rack as per size

- Mainmotor – 2 h.p

- Spindle speed – fix as per cutting material

- Cutting size maker – rack system with rechet.

- Cutting accuracy – 0.5mm

- Cutting stroke – 30 cut / minute

- Cutter size – 4 inch & 6 inch

- Base mount by Machine – MS Structure

- Cutting shaft – 1 nos with pp coating

- Cutter size – 4 inch & 6 inch

- Core gripping – manual 3 jaw chuck

- Movement assembly – harden roll dia 40mm

- Optimum strength

- High efficiency

- Precisely engineered

- Fully pneumatic machine

- Rewind shaft air shaft

- Unwinder side pressure roll

- Easy operated

- Auto counting & stopping meter

- Fully MS Structure